Our state-of-art manufacturing set-up covers the relevant equipment for precision component and assembly manufacturing. The set-up is tuned for both batch type as well as mass manufacturing. The layout is designed to ensure seamless manufacturing.

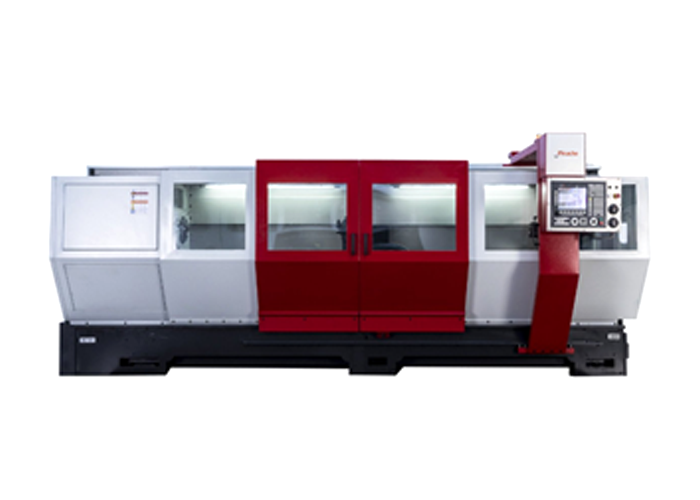

CNC Turning & Turn-mills

Cutting Machines

Conventional Set up

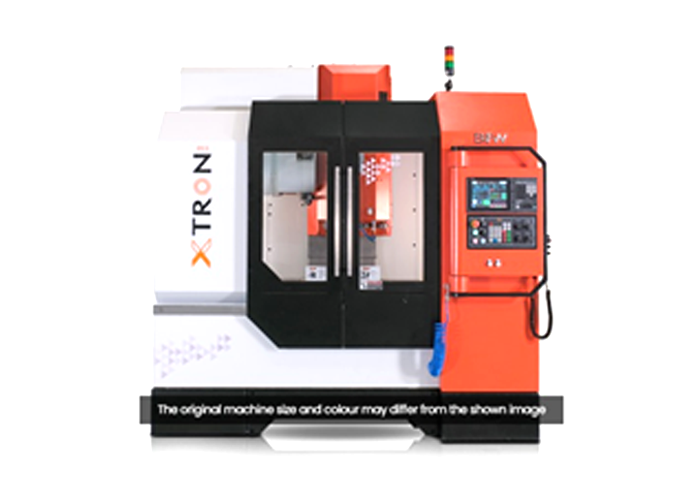

VMC Machines

Grinding & Wire cut Machines

Measurement Capability

Robotic Welding

Robotic Welding

Ultrasonic cleaning Machine

| Process / Operation | Min-Max Dia /Size | Max Length / Ht. | Toleranc | Raw Material |

|---|---|---|---|---|

| Cutting | 10 – 250 | 2800 | 0.5 | Low, Medium & High Carbon Steels |

| CNC Turning | 10 – 350 | 2800 | 0.05 | Bronze |

| CNC Turning / Milling | 5 – 250 | 550 | 0.015 | Aluminum |

| VMC & HMC | 1000 X 6000 | 2000 (ht) | 0.05 | Brass |

| VTL | 1000 X 1200 X 1200 | 1200 | 0.05 | Stainless Steel |

| Centre less Grinding | 14 – 100 | 4000 | 0.008 | Exotic Materials viz. Tungsten, Inconel, Titanium |

| Internal Grinding | 6 – 120 | 180 | 0.01 | - |

| External Grinding | 5 – 350 | 3800 | 0.005 | - |

| Surface Grinding | 250 X 400 | 200 | 0.010 | - |

| Wire cutting | 450 X 350 X 450 | 450 | 0.025 | - |

| Robotic Welding | 1000 X 1000 X 1000 | 1000 | 0.5 | - |

| Press/Stamping | 200 X 200 X 200 | - | - | - |

| Bending | 150 X 3000 | - | - | - |

| Surface Finish 0.2 Ra | ||||

| Note: For CNC Turning – Diameter Depends on Length | ||||